MX200 Features

- Rango de medición de presión máxima de 1*10-11 a 10.000 Torr

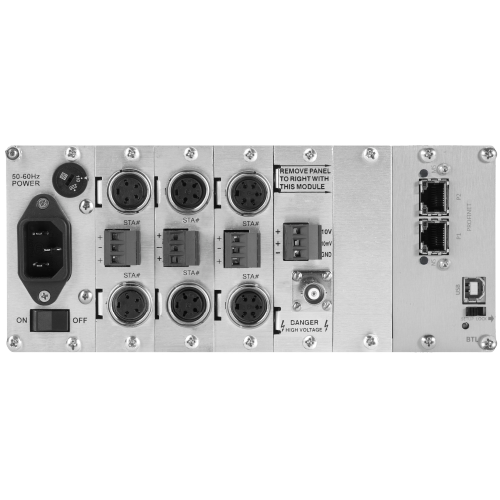

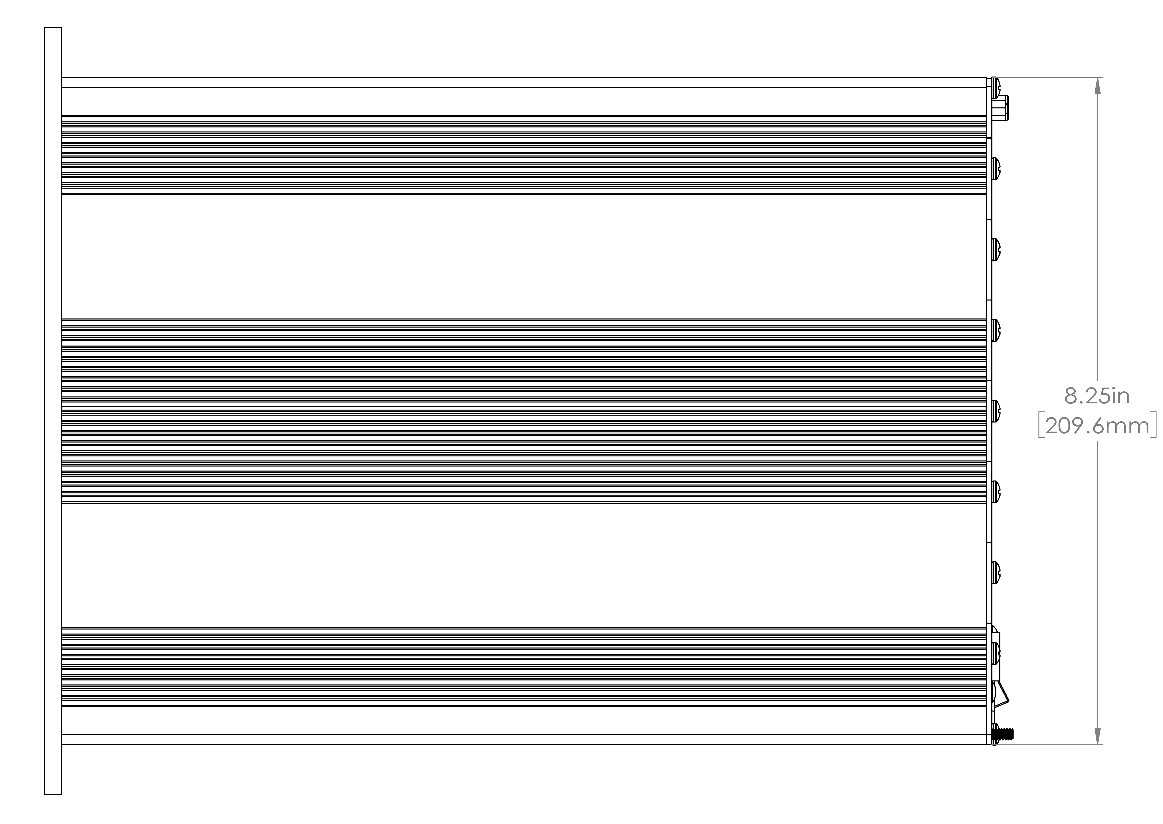

- Diseño altamente configurable y montable en bastidor

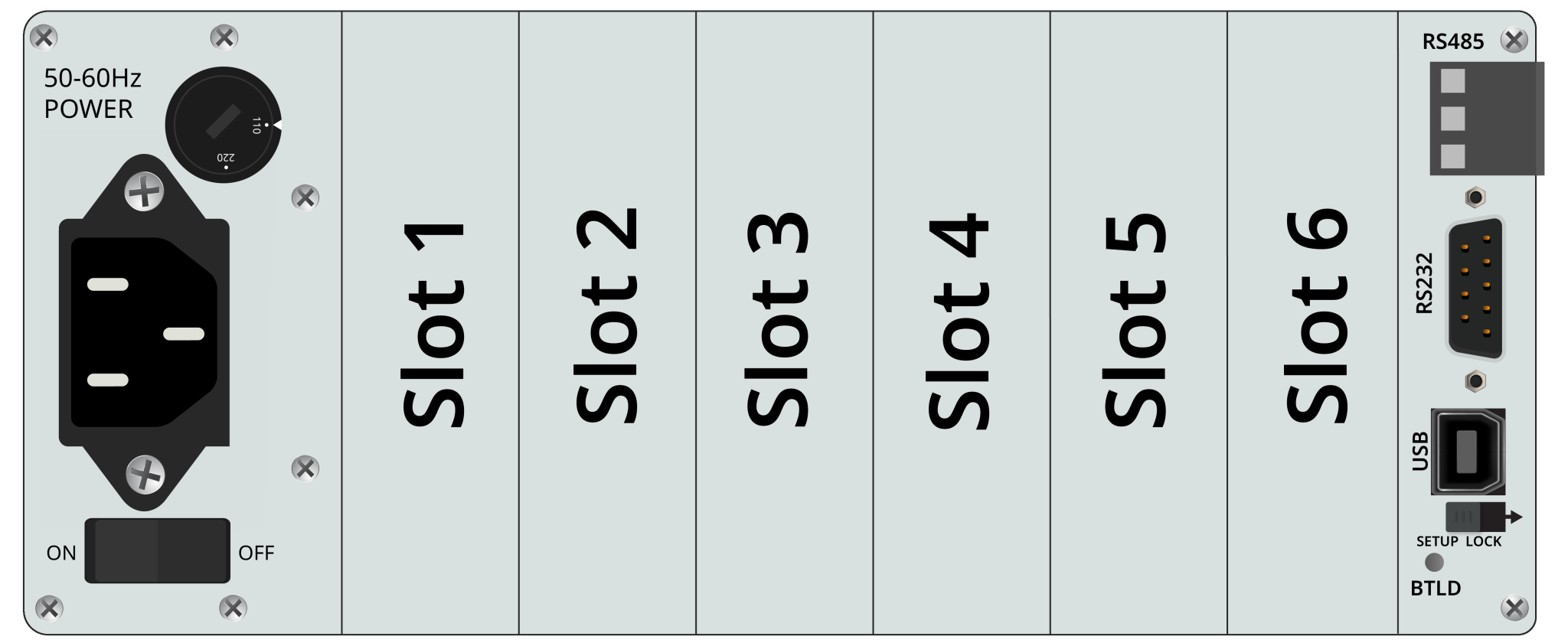

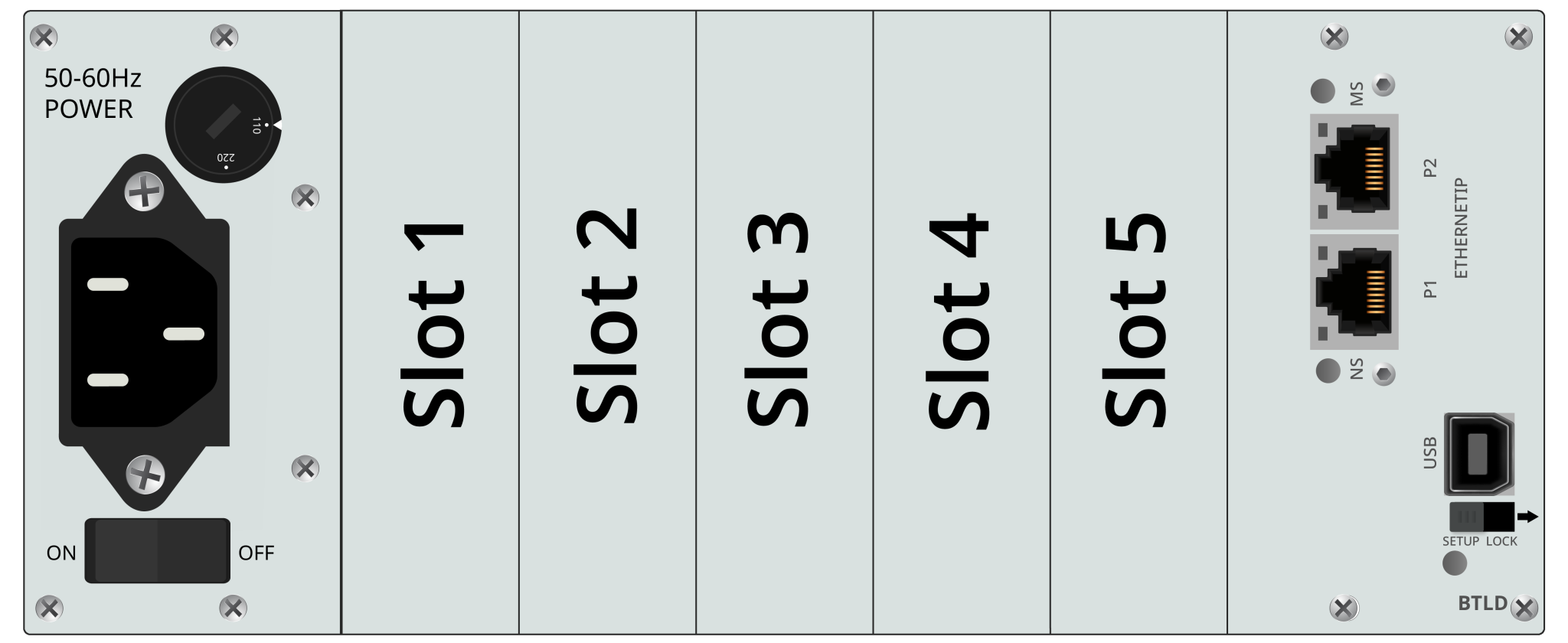

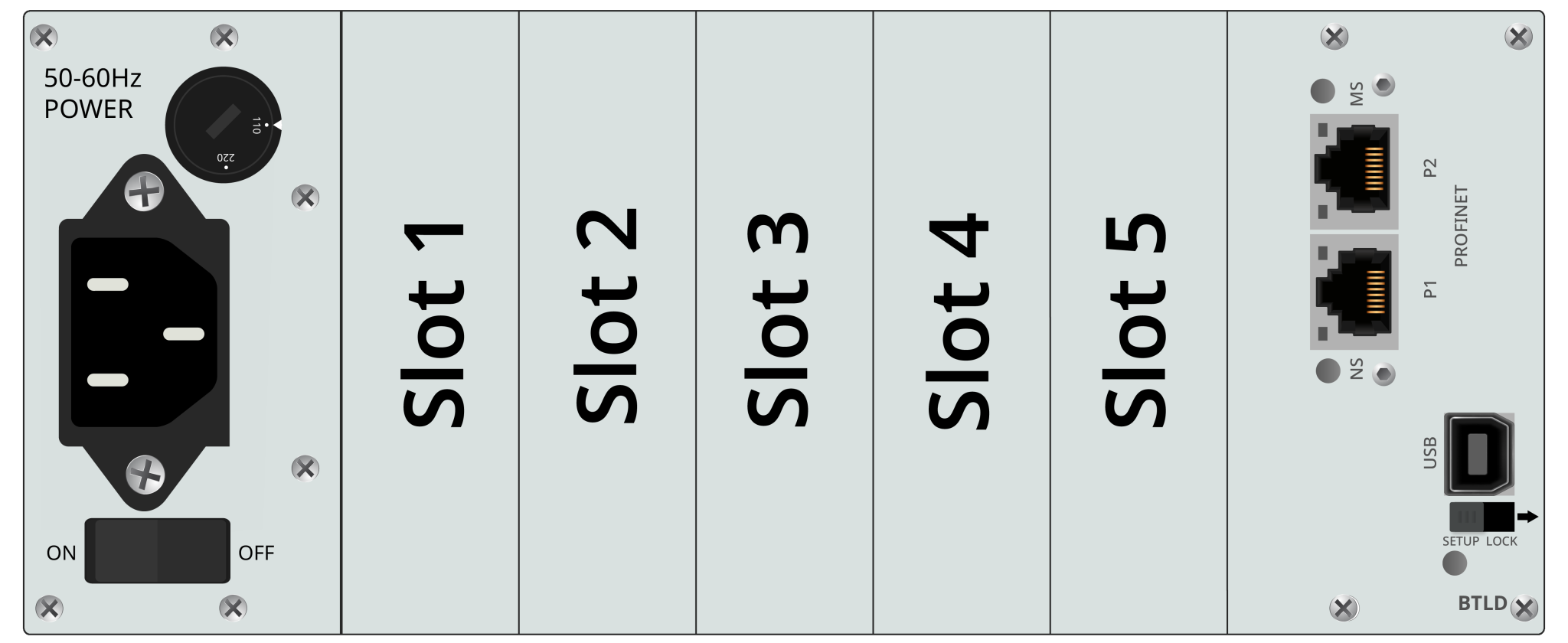

- RS-232, RS-485, EthernetIP, PROFINET, and USB communications options available

- Up to 10 configurable analog outputs (0 to 10 V DC)

- Up to 8 set point relay outputs

- Pantalla OLED de alto contraste con un ángulo de visión de 180°.

- Unidades de medida seleccionables (Torr, mbar, Pascal)

- Admite gases de nitrógeno/aire, argón, hidrógeno, helio, neón, criptón, dióxido de carbono

- Calibraciones con acreditación ISO 17025 y trazabilidad NIST disponibles

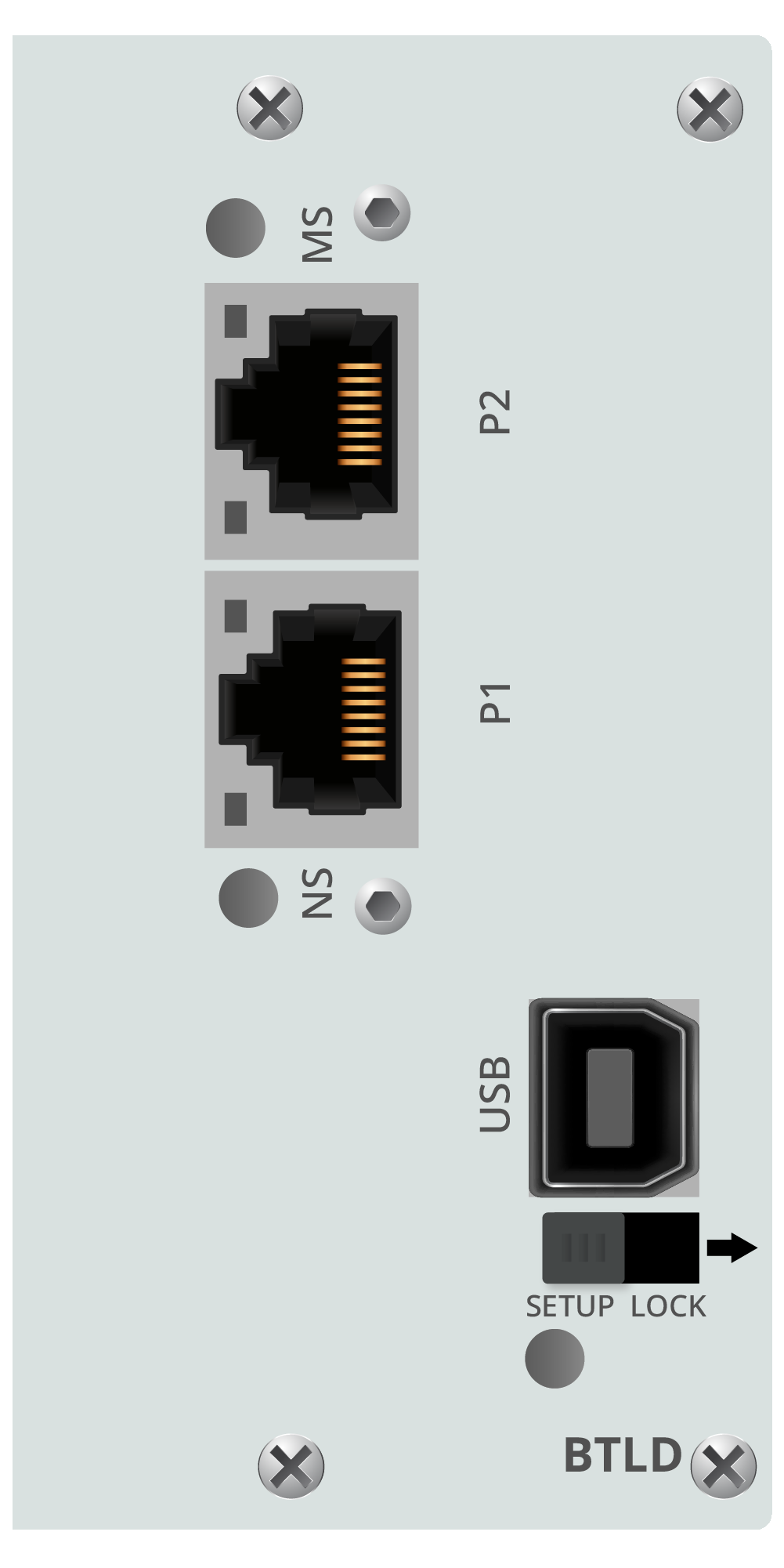

EthernetIP Features

- 10/100 Mbit, operación de puerto half o full duplex

- Habilitar o deshabilitar el DHCP con dirección IP programable

- LEDs de estado de la red/estado del módulo/actividad de los datos del puerto

- Acceso seguro a la web para los datos y ajustes de la red y la unidad

PROFINET Features

- 100 Mbit, full duplex port operation

- LEDs de estado de la red/estado del módulo/actividad de los datos del puerto

- RJ45 (2) ports for simple integration for new and existing designs

| Rango de operación | 1*10-11 Torr a 10.000 Torr |

| Comunicaciones | RS-232/RS-485/USB, EthernetIP/USB, or PROFINET/USB |

| Salida analógica | 0 a 10 V DC (1 por sensor) |

| Resolución de la salida analógica | 16 Bits |

| Puntos de ajuste programables | 4 por módulo (8 máximo) |

| Tipo de punto de ajuste | Relevo |

| Voltaje de suministro | 115/230 V CA (2/1 A), 50-60 Hz |

| Máxima potencia | 230 W |

| Medio de calibración | Aire seco o nitrógeno |

| Temperatura de funcionamiento | 0 °C a 50 °C |

| Temperatura de almacenamiento | -20 °C a 70 °C |

| Distancia de lectura de la pantalla | 5 m (16 pies) |

| Sensores máximos controlados | 10 |

| Sensores máximos mostrados | 8 |

| Tiempo de respuesta | ≤10 ms |

| RS-232 D-Sub de 9 clavijas | Descripción |

| D-Sub Clavija 1 | Suelo |

| D-Sub Clavija 2 | RS-232 TX |

| D-Sub Clavija 3 | RS-232 RX |

| D-Sub Clavija 4 | Sin conexión |

| D-Sub Clavija 5 | Suelo |

| D-Sub Clavija 6 | Sin conexión |

| D-Sub Pin 7 | Suelo |

| D-Sub Clavija 8 | Sin conexión |

| D-Sub Pin 9 | Suelo |

| RS-485 3 patillas | Descripción |

| Clavija 1 de 3 contactos | RS-485 B (+) |

| Pin 2 de 3 clavijas | RS-485 A (-) |

| Pino de 3 clavijas 3 | Suelo |

| Otros | Descripción |

| USB | Comunicaciones USB |

| Bloqueo de configuración | Interruptor de bloqueo del panel frontal |

| BTLD | Botón de arranque |

| PROFINET/EthernetIP/USB | Descripción |

| P1 | Industrial Ethernet RJ45 port 1 |

| P2 | Industrial Ethernet RJ45 port 2 |

| NS | Network status LED |

| MS | LED de estado del módulo |

| USB | Comunicaciones USB |

| Bloqueo de configuración | Interruptor de bloqueo del panel frontal |

| BTLD | Botón de arranque |

The MX200 has up to eight relay set points. The relays are located on two optional relay modules with four set points each. Individual relay statuses are displayed on the front panel.The heavy-duty relays have an SPDT (1 Form C) contact form and are rated for 24 V DC. They have a maximum currentrating of 8 A at 250 V AC or 5 A at 30 V DC.

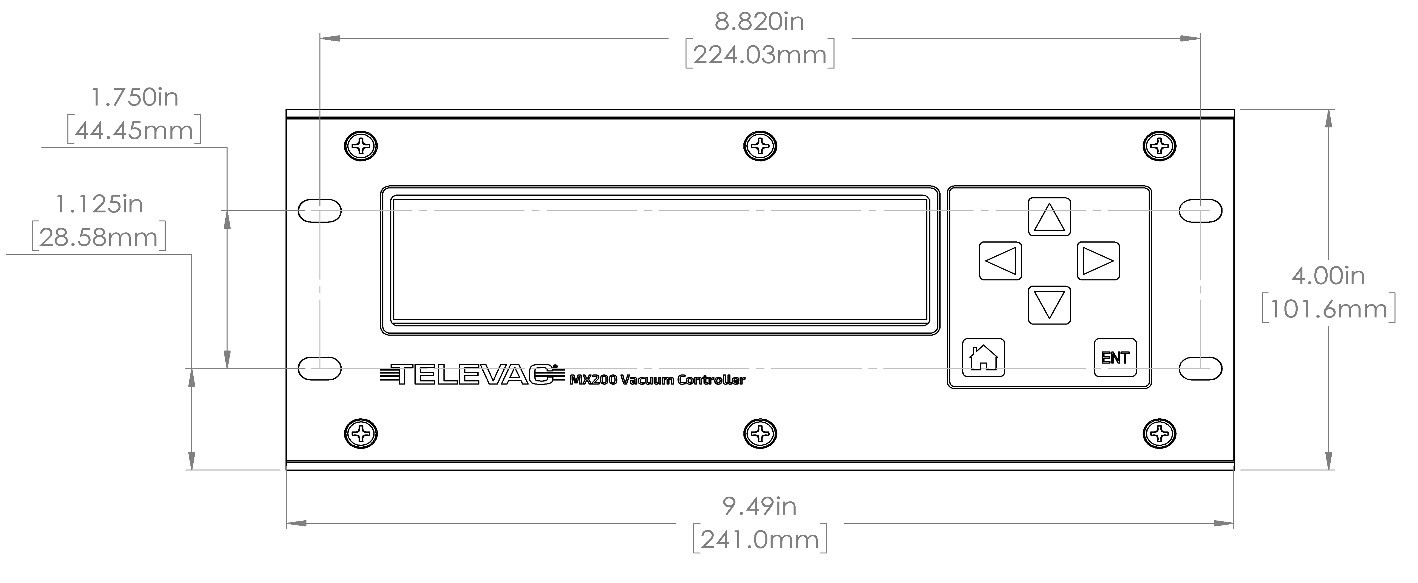

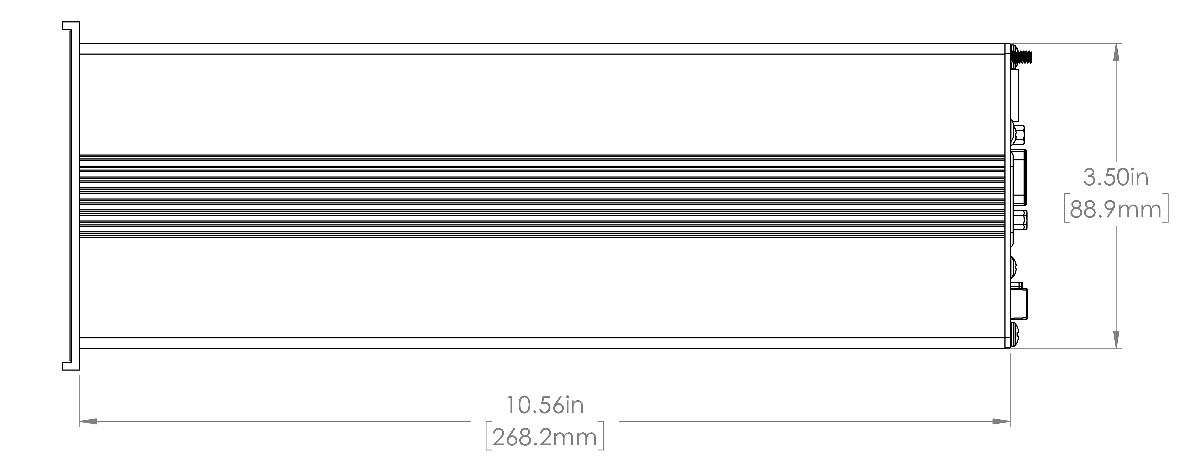

| Vivienda | Aluminio |

| Conexiones eléctricas | Cable de alimentación (IEC 60320 C-13) |

| Peso (unidad base) | 2,2 kg (5 libras) |

| Instrumento | Número de parte | Slots Available |

| MX200 Base Unit RS-232/RS-485/USB | 2-7900-034 | 6 |

| MX200 Base Unit EthernetIP/USB | 2-7900-037 | 5 |

| MX200 Base Unit PROFINET/USB | 2-7900-038 | 5 |

| Módulo | Número de parte | Ranura (máx.) |

| Set Point Quad Relay Module | 2-6200-411 | 1 (2) |

| 1E Módulo de doble diafragma piezoeléctrico | 2-6200-220 | 1 (5) |

| 1F Módulo de diafragma de doble piezoeléctrico | 2-6200-244 | 1 (5) |

| 2A Módulo de Termopar Dual | 2-6200-486 | 1 (5) |

| 4A Módulo de doble convección | 2-6200-415 | 1 (5) |

| 7B Módulo de cátodo frío de magnetrón Penning | 2-6200-227 | 2 (3) |

| 7EF DI Magnetron Cold Cathode Module | 2-6200-285 | 1 (5) |

| Capacitance Diaphragm (24 V DC) Module | 2-6200-451 | 1 (5) |

| Capacitance Diaphragm (15 V DC) Module | 2-6200-452 | 1 (5) |

Controlador de vacío MX200 |

Controlador de vacío MX200 EthernetIP |

|

|

MX200 PROFINET Vacuum Controller |

|

|

| Certificado según UL 61010-1 |

| Certificación CE según EN61326-1:2006 |

| Certificado según CAN/CSA C22.2 nº 61010-1-12 |

| Certificado EAC |

| ISO 17025 accredited calibration optional |

| NIST traceable calibration optional |

Controlador de vacío MX200

The Televac® MX200 vacuum controller, also known as a vacuum control unit or vacuum pressure controller, provides reliable and precise vacuum pressure measurements. It connects seamlessly with up to 10 passive Televac® vacuum gauges, including cold cathode, convection, piezo diaphragm, capacitance diaphragm, and thermocouple vacuum gauges. This versatile combination offers an extensive measurement range from 1*10-11 Torr to 10,000 Torr. It is well-suited for a variety of demanding applications across diverse markets, including heat treating, national laboratories, particle accelerators, cryogenics, semiconductor manufacturing, and more!

The MX200 vacuum controller includes individual 0 to 10 V DC analog outputs for each connected vacuum gauge, facilitating straightforward integration into various systems. The MX200 supports multiple gas types such as nitrogen/air, argon, hydrogen, helium, neon, krypton, and carbon dioxide, allowing you to tailor the controller to your specific vacuum application requirements.

Advanced User Interface

The MX200 vacuum controller features a user-friendly interface with six intuitive touch controls and a high-contrast OLED display. This display offers a wide 180° viewing angle and shows the measurements from up to eight connected vacuum gauges. It conveniently displays units of measurement and set point relays and automatically adjusts text size depending on the number of measurements shown, ensuring readability in various operating environments.

Modular and Customizable Design

The MX200 vacuum controller is designed to provide exceptional versatility and customization options. You can connect up to 10 Televac® vacuum gauges tailored specifically for your application. Additionally, the controller can be equipped with up to 8 optional set point relays for precise vacuum process control. To seamlessly integrate into your existing PLC system or PC, we offer multiple communication choices, including RS-232, RS-485, EthernetIP, PROFINET, and USB.

Digital Communication Options

RS-232/RS-485/USB

The standard MX200 vacuum controller includes versatile RS-232, RS-485, and USB digital communication options. These communications simplify the controller’s integration into existing PC or PLC-based systems, making it ideal for a wide range of industrial vacuum applications.

EthernetIP/USB Communication

The MX200 vacuum controller is also available with EthernetIP communication. This option integrates seamlessly into industrial Ethernet environments, allowing for efficient monitoring and control over a network. Ideal for facilities already utilizing EthernetIP protocols, this version maintains all core features, including the intuitive OLED display, analog outputs, and set point relays.

PROFINET/USB Communication

For systems that utilize PROFINET protocols, the MX200 vacuum controller is available with PROFINET digital communications. This version provides easy integration into PROFINET-based industrial automation systems, ensuring reliable and efficient data communication. It retains all standard MX200 features, including the intuitive OLED display, analog outputs, and set point relays.

Complete Vacuum Solutions

Need a passive vacuum gauge to pair with your MX200? Use our product selection guide to find the ideal solution for your application. Ready to configure and purchase your MX200 vacuum controller? Visit our MX200 Online Order Hub and get started!

Documentación del producto

| Hoja de datos del MX200 |

| Manual de instrucciones del MX200 |

| Tolerancias de calibración de vacío Televac |

Modelo 3D (archivo STEP)

| Controlador de vacío MX200 Archivo STEP |

Notas de aplicación

| Televac® Application Note 3008: MX200 to PC Interfacing and Communications |

| Televac® Application Note 3011: MX200 and MM200 Analog Output Comparisons |

Videos

| Vídeo de demostración del MX200 |

Herramientas

| Centro de pedidos en línea MX200 |

| Vacuum Leak Rate Converter |

| Convertidor de medición de vacío |

| Terminal serie web |

Casos prácticos

| Estudio de caso: Laboratorio Nacional de Argonne |

Artículos

| Medición en vacío con la moderna tecnología de cátodo frío |

Folletos

Descargar archivo STEP

| Número de parte | Descripción | Archivo STEP |

| 2-7900-03X | Controlador de vacío MX200 | Descargar |