MX200 Features

- 1*10-11 to 10,000 Torr maximum pressure measurement range

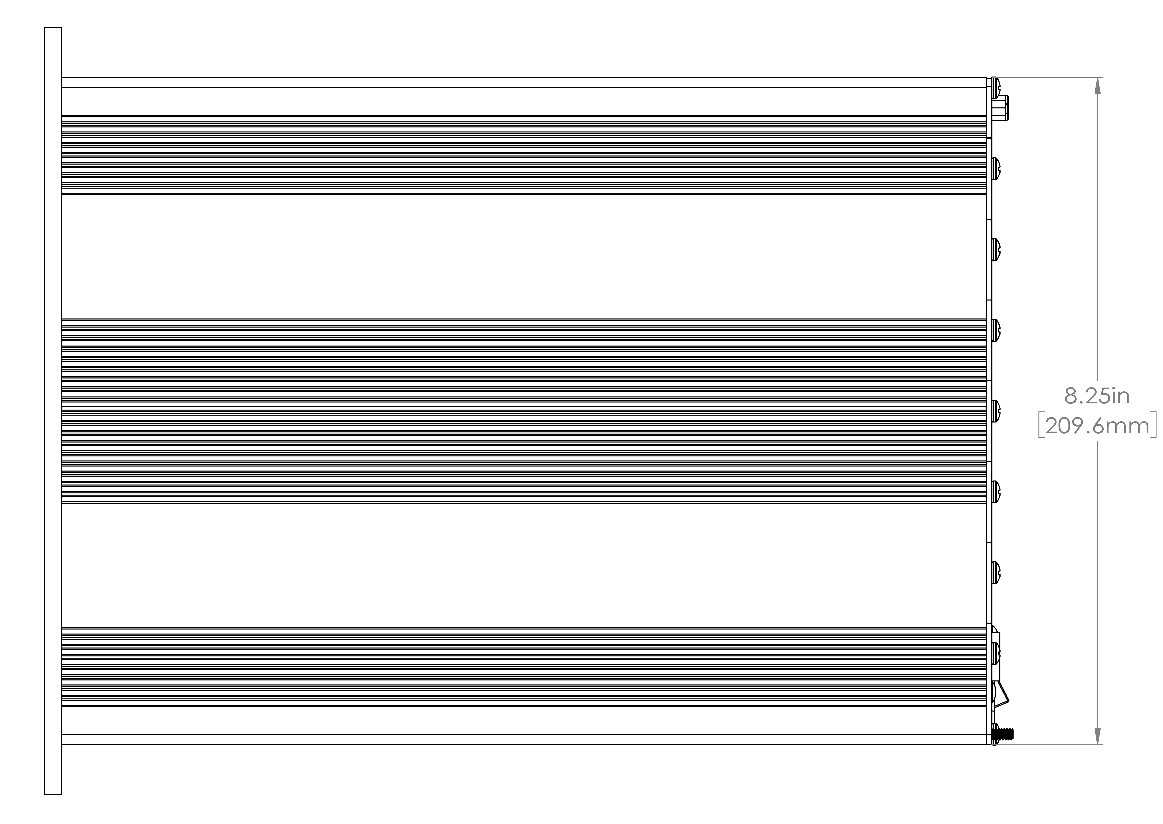

- Highly configurable, rack mountable design

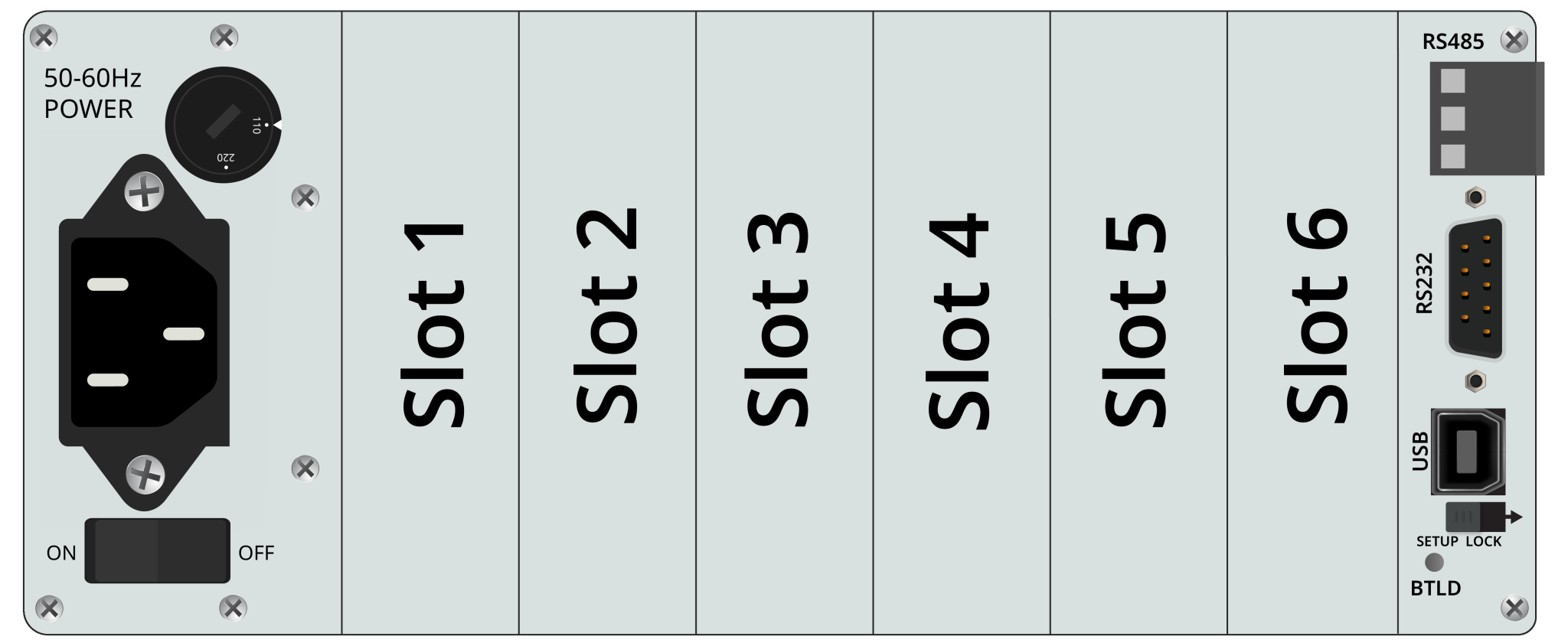

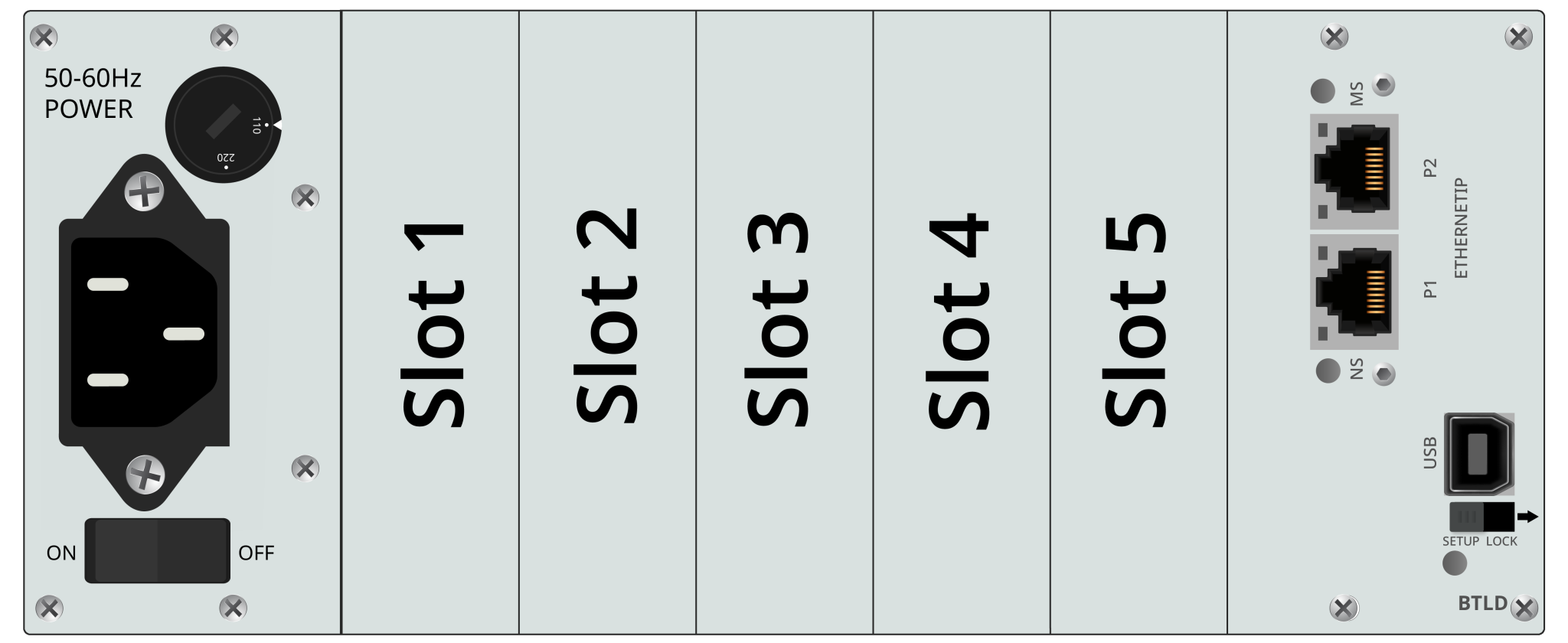

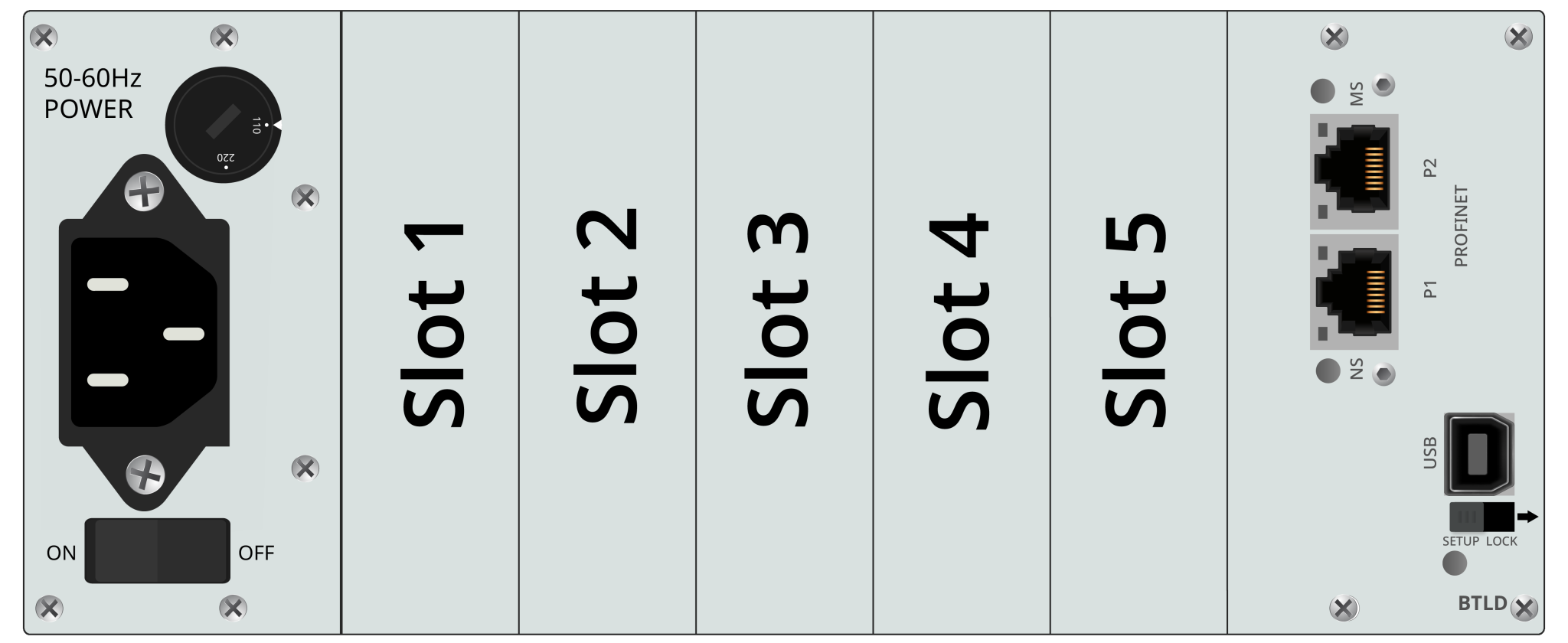

- RS-232, RS-485, EthernetIP, PROFINET, and USB communications options available

- Up to 10 configurable analog outputs (0 to 10 V DC)

- Up to 8 set point relay outputs

- High contrast OLED display with 180° viewing angle

- Selectable units of measurement (Torr, mbar, Pascal)

- Supports nitrogen/air, argon, hydrogen, helium, neon, krypton, carbon dioxide gases

- ISO 17025 accredited and NIST traceable calibrations available

EthernetIP Features

- 10/100 Mbit, half or full duplex port operation

- DHCP enable or disable with programmable IP address

- Status LEDs for network/module status/port data activity

- Secure web access for network and unit data and settings

PROFINET Features

- 100 Mbit, full duplex port operation

- Status LEDs for network/module status/port data activity

- RJ45 (2) ports for simple integration for new and existing designs

| Operating Range | 1*10-11 Torr to 10,000 Torr |

| Communications | RS-232/RS-485/USB, EthernetIP/USB, or PROFINET/USB |

| Analog Output | 0 to 10 V DC (1 per sensor) |

| Analog Output Resolution | 16 Bits |

| Programmable Set Points | 4 per module (8 max) |

| Set Point Type | Relay |

| Supply Voltage | 115/230 V AC (2/1 A), 50-60Hz |

| Maximum Power | 230 W |

| Calibration Medium | Dry air or nitrogen |

| Operating Temperature | 0 °C to 50 °C |

| Storage Temperature | -20 °C to 70 °C |

| Display Readable Distance | 5 m (16 ft) |

| Maximum Sensors Controlled | 10 |

| Maximum Sensors Displayed | 8 |

| Response Time | ≤10 ms |

| RS-232 D-Sub 9 Pin | Description |

| D-Sub Pin 1 | Ground |

| D-Sub Pin 2 | RS-232 TX |

| D-Sub Pin 3 | RS-232 RX |

| D-Sub Pin 4 | No Connection |

| D-Sub Pin 5 | Ground |

| D-Sub Pin 6 | No Connection |

| D-Sub Pin 7 | Ground |

| D-Sub Pin 8 | No Connection |

| D-Sub Pin 9 | Ground |

| RS-485 3 Pin | Description |

| 3-Pin Pin 1 | RS-485 B (+) |

| 3-Pin Pin 2 | RS-485 A (-) |

| 3-Pin Pine 3 | Ground |

| Other | Description |

| USB | USB communications |

| Setup lock | Front panel lock switch |

| BTLD | Bootload button |

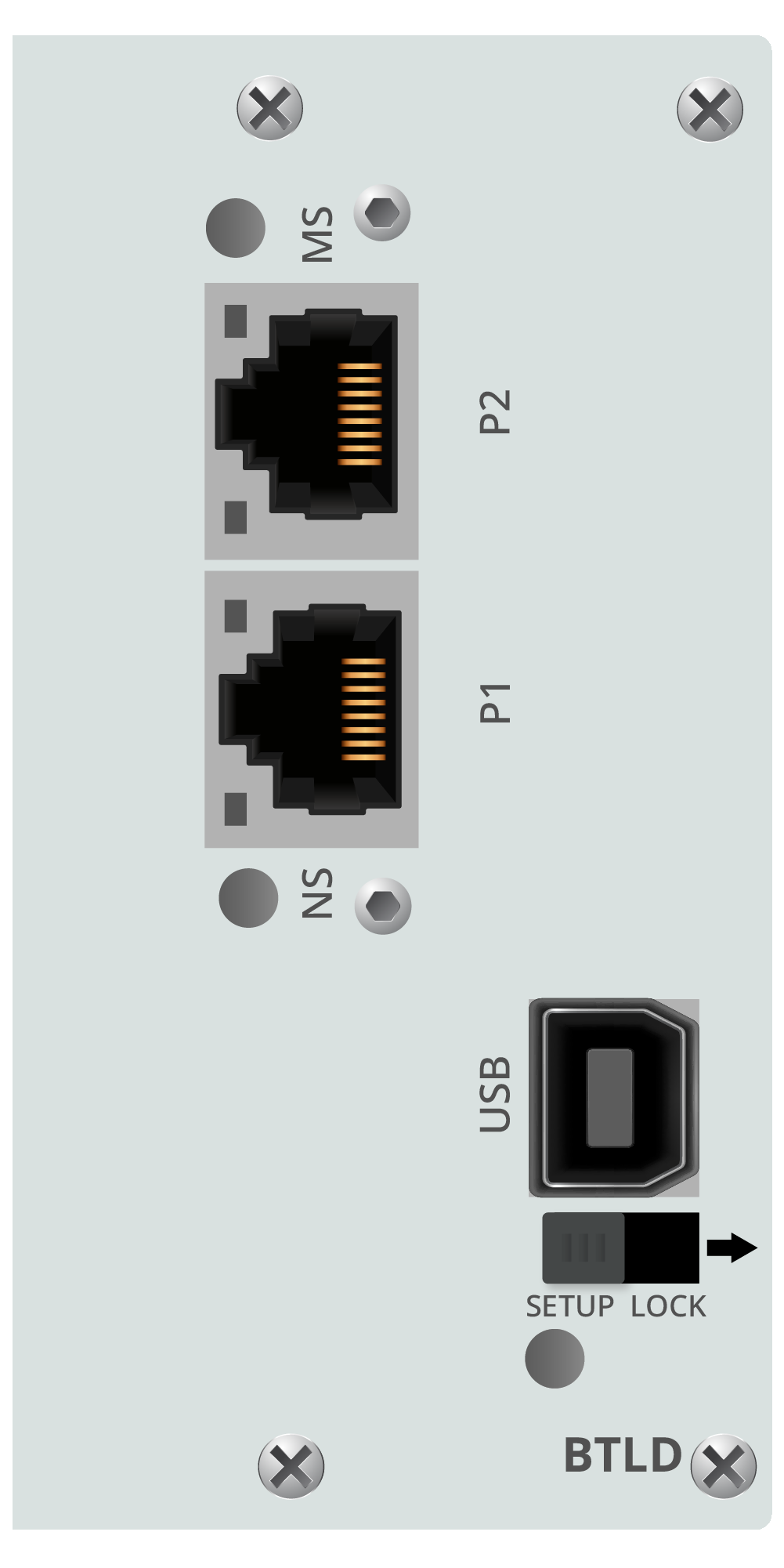

| PROFINET/EthernetIP/USB | Description |

| P1 | Industrial Ethernet RJ45 port 1 |

| P2 | Industrial Ethernet RJ45 port 2 |

| NS | Network status LED |

| MS | Module status LED |

| USB | USB communications |

| Setup Lock | Front panel lock switch |

| BTLD | Bootload button |

The MX200 has up to eight relay set points. The relays are located on two optional relay modules with four set points each. Individual relay statuses are displayed on the front panel.The heavy-duty relays have an SPDT (1 Form C) contact form and are rated for 24 V DC. They have a maximum currentrating of 8 A at 250 V AC or 5 A at 30 V DC.

| Housing | Aluminum |

| Electrical Connections | Power cord (IEC 60320 C-13) |

| Weight (Base Unit) | 2.2 kg (5 lbs) |

| Instrument | Part Number | Slots Available |

| MX200 Base Unit RS-232/RS-485/USB | 2-7900-034 | 6 |

| MX200 Base Unit EthernetIP/USB | 2-7900-037 | 5 |

| MX200 Base Unit PROFINET/USB | 2-7900-038 | 5 |

| Module | Part Number | Slot (max) |

| Set Point Quad Relay Module | 2-6200-411 | 1 (2) |

| 1E Dual Piezo Diaphragm Module | 2-6200-220 | 1 (5) |

| 1F Dual Piezo Diaphragm Module | 2-6200-244 | 1 (5) |

| 2A Dual Thermocouple Module | 2-6200-486 | 1 (5) |

| 4A Dual Convection Module | 2-6200-415 | 1 (5) |

| 7B Penning Magnetron Cold Cathode Module | 2-6200-227 | 2 (3) |

| 7EF DI Magnetron Cold Cathode Module | 2-6200-285 | 1 (5) |

| Capacitance Diaphragm (24 V DC) Module | 2-6200-451 | 1 (5) |

| Capacitance Diaphragm (15 V DC) Module | 2-6200-452 | 1 (5) |

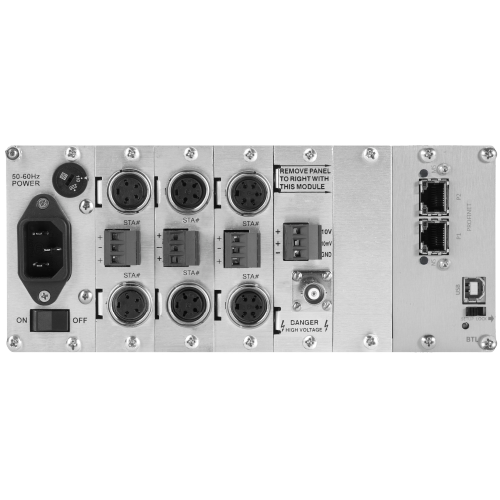

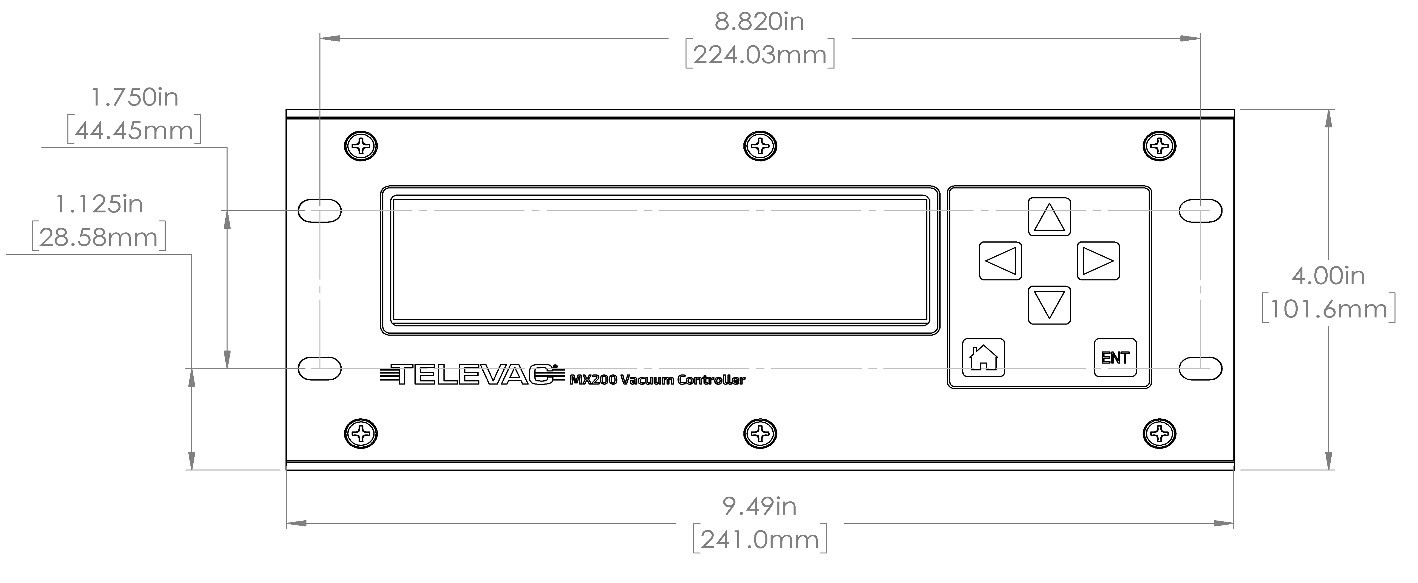

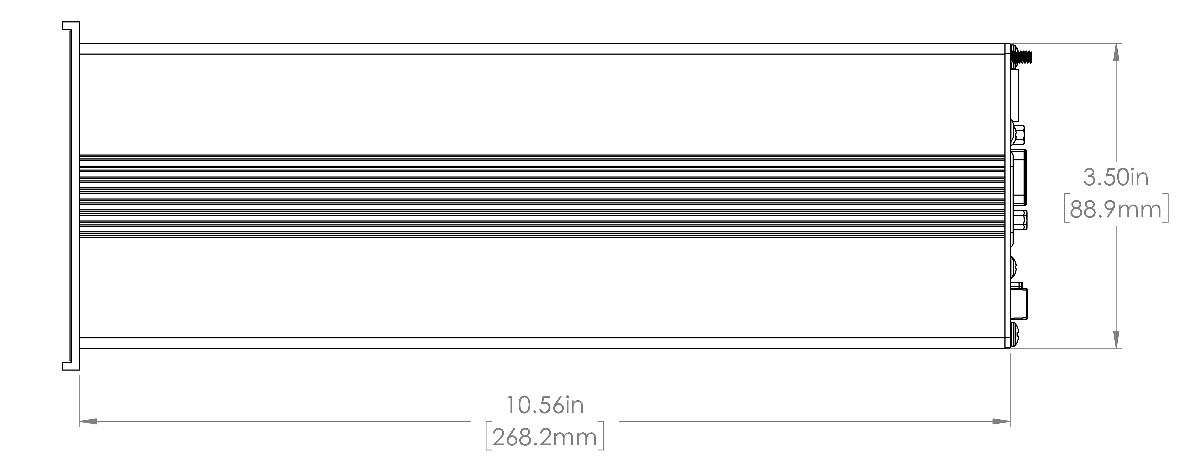

MX200 Vacuum Controller |

MX200 EthernetIP Vacuum Controller |

|

|

MX200 PROFINET Vacuum Controller |

|

|

| Certified to UL 61010-1 |

| CE certified to EN61326-1:2006 |

| Certified to CAN/CSA C22.2 No. 61010-1-12 |

| EAC certified |

| ISO 17025 accredited calibration optional |

| NIST traceable calibration optional |

MX200 Vacuum Controller

The Televac® MX200 vacuum controller, also known as a vacuum control unit or vacuum pressure controller, provides reliable and precise vacuum pressure measurements. It connects seamlessly with up to 10 passive Televac® vacuum gauges, including cold cathode, convection, piezo diaphragm, capacitance diaphragm, and thermocouple vacuum gauges. This versatile combination offers an extensive measurement range from 1*10-11 Torr to 10,000 Torr. It is well-suited for a variety of demanding applications across diverse markets, including heat treating, national laboratories, particle accelerators, cryogenics, semiconductor manufacturing, and more!

The MX200 vacuum controller includes individual 0 to 10 V DC analog outputs for each connected vacuum gauge, facilitating straightforward integration into various systems. The MX200 supports multiple gas types such as nitrogen/air, argon, hydrogen, helium, neon, krypton, and carbon dioxide, allowing you to tailor the controller to your specific vacuum application requirements.

Advanced User Interface

The MX200 vacuum controller features a user-friendly interface with six intuitive touch controls and a high-contrast OLED display. This display offers a wide 180° viewing angle and shows the measurements from up to eight connected vacuum gauges. It conveniently displays units of measurement and set point relays and automatically adjusts text size depending on the number of measurements shown, ensuring readability in various operating environments.

Modular and Customizable Design

The MX200 vacuum controller is designed to provide exceptional versatility and customization options. You can connect up to 10 Televac® vacuum gauges tailored specifically for your application. Additionally, the controller can be equipped with up to 8 optional set point relays for precise vacuum process control. To seamlessly integrate into your existing PLC system or PC, we offer multiple communication choices, including RS-232, RS-485, EthernetIP, PROFINET, and USB.

Digital Communication Options

RS-232/RS-485/USB

The standard MX200 vacuum controller includes versatile RS-232, RS-485, and USB digital communication options. These communications simplify the controller’s integration into existing PC or PLC-based systems, making it ideal for a wide range of industrial vacuum applications.

EthernetIP/USB Communication

The MX200 vacuum controller is also available with EthernetIP communication. This option integrates seamlessly into industrial Ethernet environments, allowing for efficient monitoring and control over a network. Ideal for facilities already utilizing EthernetIP protocols, this version maintains all core features, including the intuitive OLED display, analog outputs, and set point relays.

PROFINET/USB Communication

For systems that utilize PROFINET protocols, the MX200 vacuum controller is available with PROFINET digital communications. This version provides easy integration into PROFINET-based industrial automation systems, ensuring reliable and efficient data communication. It retains all standard MX200 features, including the intuitive OLED display, analog outputs, and set point relays.

Complete Vacuum Solutions

Need a passive vacuum gauge to pair with your MX200? Use our product selection guide to find the ideal solution for your application. Ready to configure and purchase your MX200 vacuum controller? Visit our MX200 Online Order Hub and get started!

Product Documentation

| MX200 Datasheet |

| MX200 Instruction Manual |

| Televac® Vacuum Calibration Tolerances |

3D Model (STEP File)

| MX200 Vacuum Controller STEP File |

Application Notes

| Televac® Application Note 3008: MX200 to PC Interfacing and Communications |

| Televac® Application Note 3011: MX200 and MM200 Analog Output Comparisons |

Videos

| MX200 Demonstration Video |

Tools

| MX200 Online Order Hub |

| Vacuum Leak Rate Converter |

| Vacuum Measurement Converter |

| Web Serial Terminal |

Case Studies

| Case Study: Argonne National Laboratory |

Articles

| Vacuum Measurement Using Modern Cold Cathode Technology |

Brochures

Download STEP File

| Part Number | Description | STEP File |

| 2-7900-03X | MX200 Vacuum Controller | Download |